A real masterpiece: this metal reach, high temperature environment is less than ideal to apply wireless electronics. This special ERL design is able to withstand temperatures higher than 180 oC.

The sensor communicates via a special designed housing to a EVDL base station that distributes the measurement data the a Siemens S7 PLC for further processing and visualisation.

This solution enables Andritz to incorporate temperature measurements on virtually any of there new and brownfield equipment, gaining better inside into there machine performance and giving better feedback to customers as to their processing without altering there machine controls.

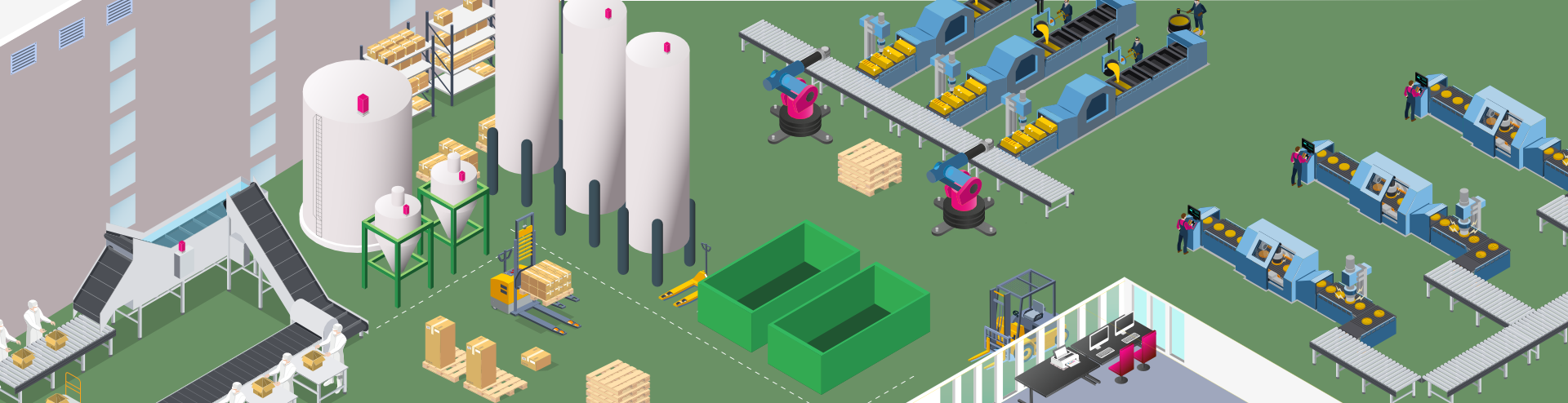

This supplier of high quality solids handling equipment offers excellent products that are part of critical processes where stand still and contamination are not allowed.

To reduce the total cost of ownership and increase availability, this machine builder has chosen to improve its ability to predict degradation and align with its customers to plan maintenance during production changeovers.

UVS predictive maintenance solution has been applied @ four customers sites with great success. Besides increasing availability, degradation patterns gave these customers more confidence in the equipment quality, showed what the effect of certain production processes have on equipment and decreased production loss by at least 12%. Overall savings have been 800+ % times the additional investment within the first 6 months.

Asset owners are looking for capacity rather than buying a machine, assets are leased or rented. To enable machine builders to engage in such a venture the machine stays part of the machine builders business or as we say “machines never leave the factory”.

To enable this machine builder to monitor, analyse and modify there Cobot, UVS provides streaming data and remote analyses services and hardware. From any part of the world the Cobots can be monitored and automatically scheduled for maintenance.

Further more extensive behaviour and usage logs can be obtained to provide evidence of usage and effectiveness. The Cobot business model is base don the effectiveness and uptime of the remote worker.

The incorporation of UVS technology as boosted the Cobot sales with around 200%, the amount of interventions or lookup actions reduced from 4 times a day to 1 time a week. Traveling to the customer is only needed for installation or business purposes. UVS technology has made this business grow beyond it’s set goals and 250% faster than competitors.