Predictive maintenance

OpenICM asset management AMMS* combines executive tools and functions as well as advanced analyses tools like FMECA, OEE and Predictive modeling. All modules work together without custom programming or configuration. The predictive maintenance modules have one primary goal, identify degradation and convert this into action. Secondary predictive modules provide powerful statistical information that help increasing organizational performance.

Maintenance is shifting from a necessity to a key role in every organization. Whether you a producing company that needs to meet the ever higher demand of customers or your a machine builder that shifts to a servitization model rather than a sell & service model, change is ongoing and organizations need to adopt and change. To achieve these goals in a world where skilled resources are scares and price differences have reduced to a minimum. Predictive maintenance can and will make the difference.

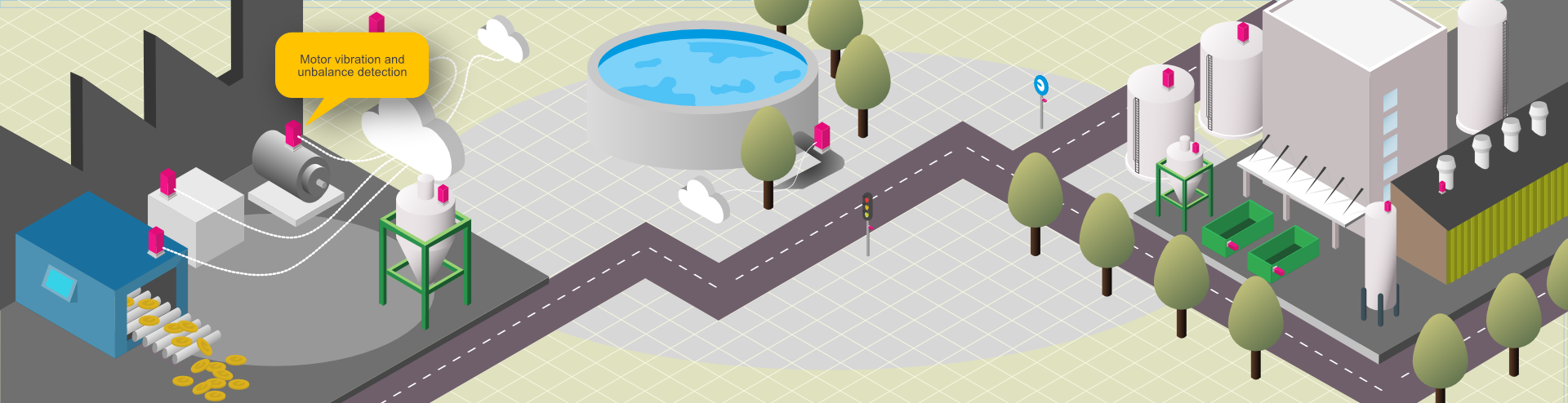

Initiatives from the past like maintenance management software, apps and monitoring systems will NOT lead to true predictive maintenance. To less maintenance efficiency have effect on the output or abilities of an organization and INTEGRAL approach is needed. Products like OpenICM (SMART assets management software) and ERL (SMART sensor technology) will impact the efficiency and availability of your organization assets.

Extensive model library

The OpenICM model library consists out of more than 3000 model of typical asset behaviors like motors, pump, valves etc. Just typecast an asset and all applicable models will be assigned to that asset.

Easy model creation

You will be able to build you own library with modified and add new models. Data scientist can easily design new models using the graphical interface or make advanced models using Python programming.

Three step predictive analyses

Local first line analyses is done at sensor level, based on common real-time relations degradation and faulty circumstances are identified. MES level analyses is done at local or cloud based server level, where line or machine behavior is analyses. At this stage specific machine behavior and asset relations are modeled analyzed. Big Data analyses considers common assets over time. Here feedback is generated and new models are deviced that will be made available at edge level.

Convert prediction into ACTION

To predict asset degradation is one, to continuously monitor and take action at the right moment is an other story. OpenICM takes predictive maintenance to the next level. Via easy to configure function blocks for each asset you can convert behavior (models) knowledge into actions. Whether the knowledge / model is from an OEM-er, Consultant or from your own brew you can now combine knowledge and take it into action.