Asset management CMMS

Industrial ASSET management enters a new era. Machines will provide information on their current, past and future condition and degradation. Automated condition and risk based maintenance scheduling and early equipment maintenance will be standard. OpenICM provides a full scale vertical and modular solution for managing your assets throughout their entire life cycle. OpenICM brings together operations, maintenance, suppliers and knowledge owners in order to find an optimal balance between costs, performance and risks. That;s way OpenICM not only provides scheduling but also OEE, FMECA and inventory management functionalities.

Complete integration from shop floor to board Modular only pay for use SaaS no installation needed Scalable applicable & affordable for one men show up to enterprise level Knowledge rich full of ready made models, templates and root causes to get you started

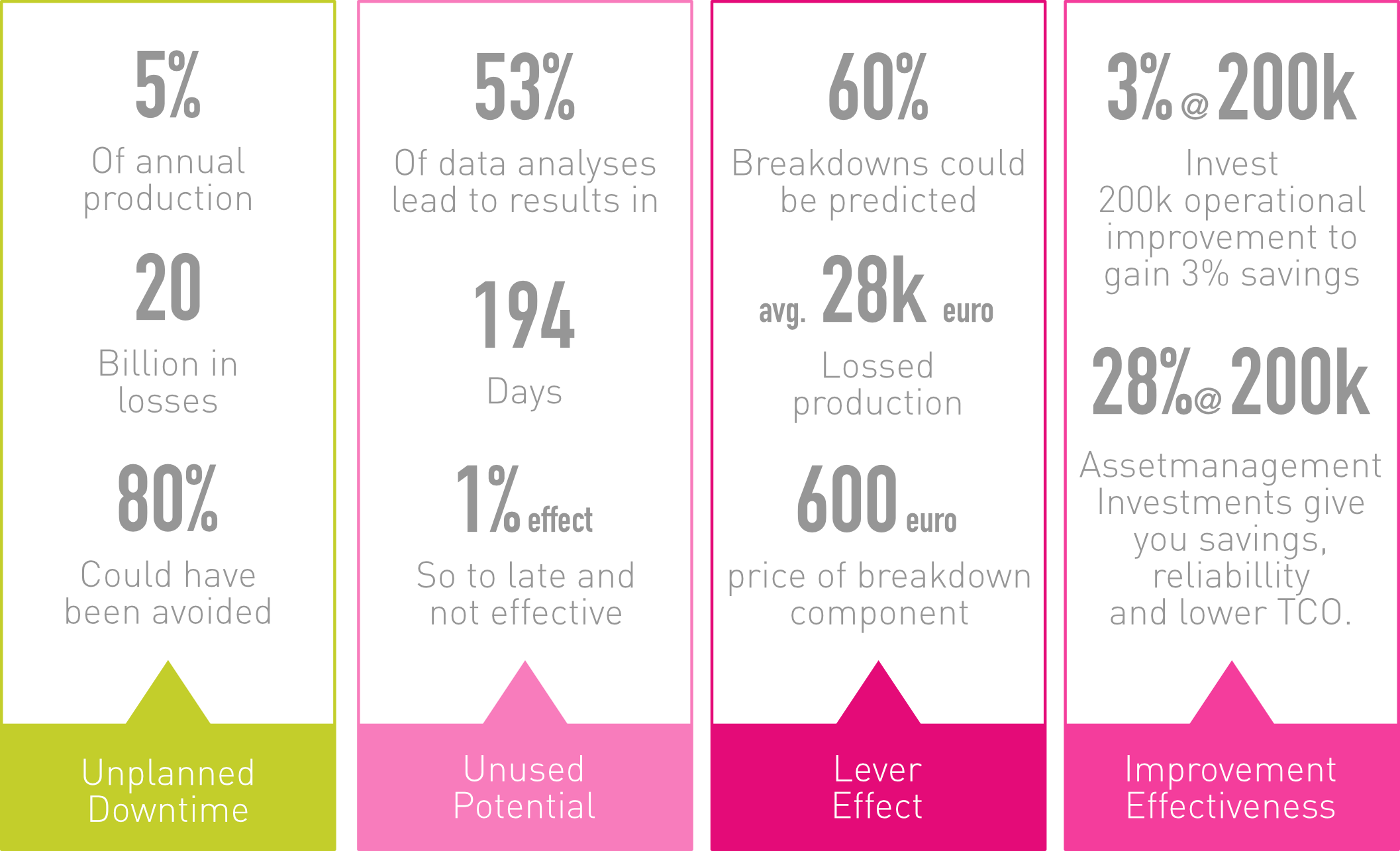

Why invest in asset management?

Asset management will make all the difference. Depending on the maturity and value chain, the benefits are clear and more effective than production focused improvement programs. Food for Though

Ever wondered why we all tolerate production loss knowing that millions are waisted while investing a same amount would have prevented even more…”

Optimal effect through vertical integration

UVS Offers an integral solution from SENSOR up to STATEGIC level dash boarding. In this way company goals (KPI’s) on each level can be aligned and bench marked against real actions, budgets, goals and availability. To bring together IT and OT environments, UVS provides “IIoT Engine”, this solution enables communication between IIoT devices and OpenICM or any Third party software.

OpenICM puts continuous improvement into practice. All modules are designed to improve future actions, advice and planning.

Strategic

Overall performance and risks. Planning for new investments. Market positioning and liability. Resource management.

- Dashboards

- Quality reporting

- OEE

Executive

Are assets and resources available, what risks are we taking, do we need budget. Optimize balance between costs and risks.

- Material management

- Resource management

- FMECA

- P&L Planning

Operational

Does operational and maintenance schedules align. Which priorities do I set, What resources do I commit.

- Task planning

- Asset state report

- Permits

Professional

Asset technical and performance information. Permits and procedures to follow. Scheduling tasks, materials and tools.

- Documents

- Assets information

- Instructions & Procedures

Easy integration

Because we are not the only solution provider in the world, our platform is open for integration with other software and is able to communicate in many different ways.

Step by Step Maintenance maturity

You need to start improving your asset control and performance improvement somewhere. OpenICM enables you to start with basic asset recording and grow along with your needs just by selecting additional modules. There’s no need for extensive engineering or consultancy. Especially for those who need to grow into a more mature asset management we offer a roadmap that takes you step by step to a higher level. Each step includes clear goals, you determine the page and the level you like to reach. The roadmap is FREE for all OpenICM customers and includes online coaching.

2nd, 3th Industrial Revolution

Up to now most producing companies have more like a repair department which does maintenance on pre defined intervals. Stock is kept to compensate for uncertainties in the supply chain and unknown failure occurrences.

- Repair knowledge is key

- Resources volumes

- Buy in to reduce risks

Industry 4.0 / SMART Maintenance

Maintenance in this era is all about maximizing availability against the lowest possible costs. Huge challenges ley ahead because technical skilled personnel is scarce and the need for more customer focus and hence more flexibility and reliability has become higher.

- Data driven

- Corporation within the supply chain

- Information transparency

- High efficiency

- 100% Identified assets

- No unpredicted failures and production stops