Maintenance 360

Maintenance is shifting from a necessity to a key role in every organization. Whether you a producing company that needs to meet the ever higher demand of customers or your a machine builder that shifts to a servitization model rather than a sell & service model, change is ongoing and organizations need to adopt and change.

To achieve these goals in a world where skilled resources are scares and price differences have reduced to a minimum. Predictive maintenance can and will make the difference.

Automated Predictive MaintenanceTo predict asset degradation is one, to continuously monitor and take action at the right moment is and other story. OpenICM takes predictive maintenance to the next level. Via easy to configure function blocks for each asset you can convert behavior (models) knowledge into actions. Whether the knowledge / model is from an OEM-er, Consultant or from your own brew you can now combine knowledge and take it into action. Request a Demo |

|

One modular integrated solutionWe know that the transition from reactive to predictive maintenance is a step by step process. That is why OpenICM is completely scalable, so take a small steps by recording assets, report breakdowns and when you are ready start predicting certain behavior. Take the journey as far a you need up to automated scheduling and degradation prediction. |

|

|

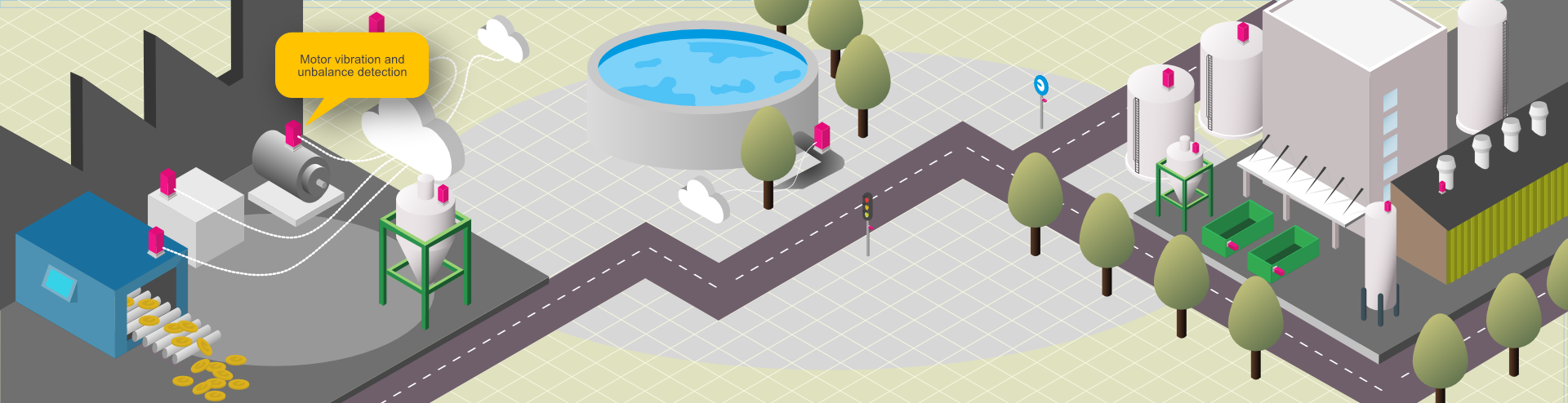

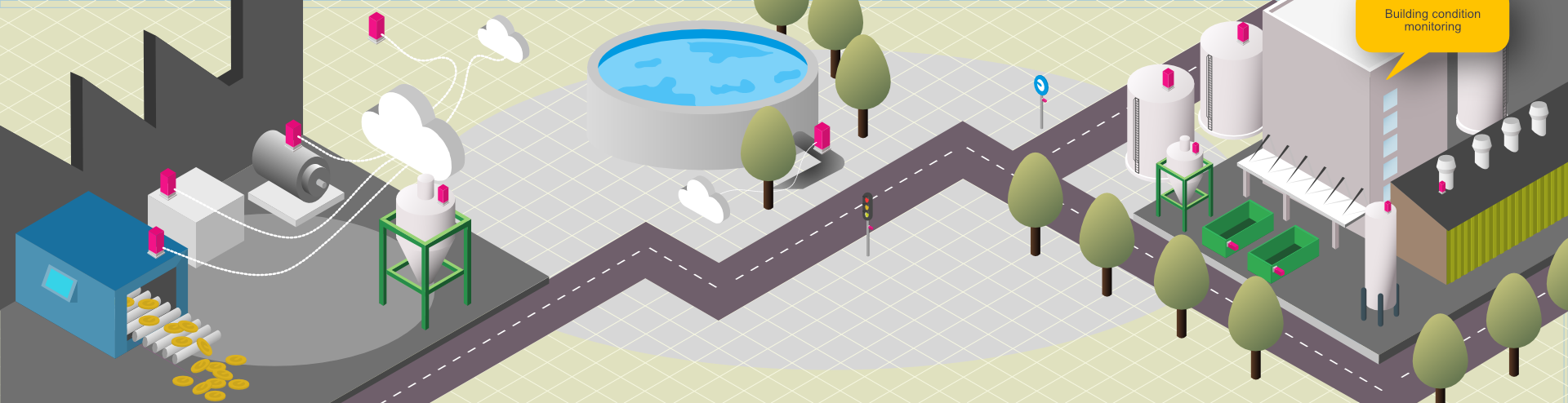

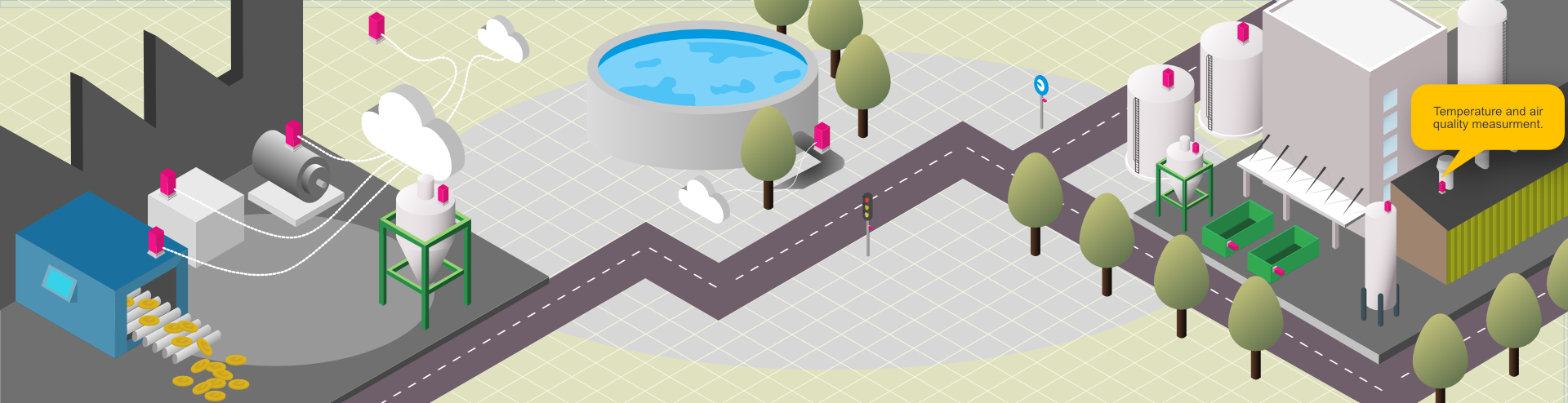

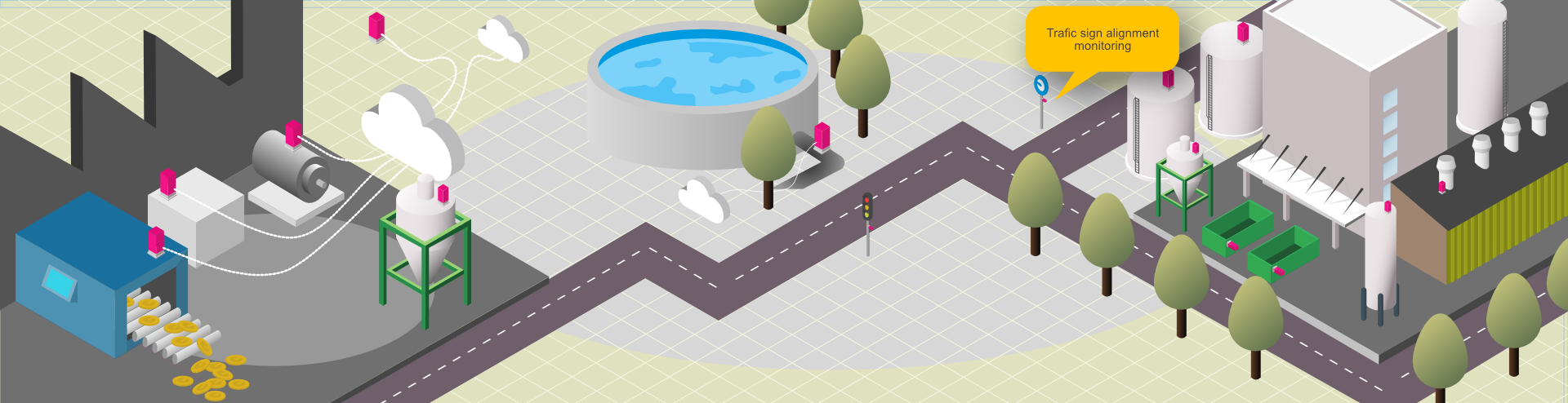

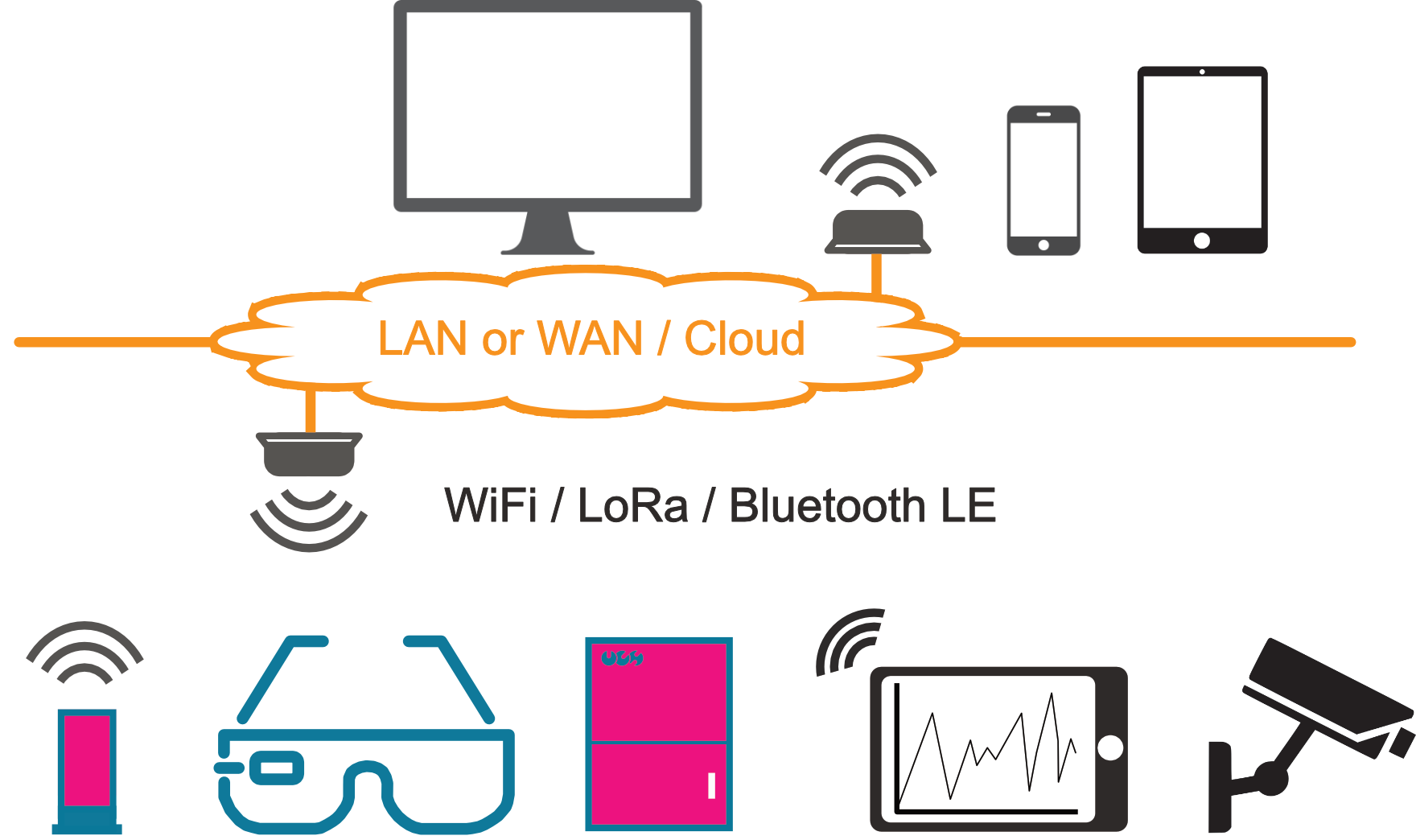

UVS Offers an integral solution from SENSOR up to STATEGIC level dash boarding. In this way company goals (KPI’s) on each level can be aligned and bench marked against real actions, budgets, goals and availability. To bring together IT and OT environments, UVS provides “IIoT Engine”, this solution enables communication between IIoT devices and OpenICM or any Third party software. Download module selections sheet

|

Keep control over the puzzleKeeping all things in mind so they perfectly align while complying to everybody’s whishes will often be a enormous challenge. Especially when situations change most often compromises are made. OpenICM keeps all strings attached and moves along changing situations easing your mind so you can focus on getting things done. OpenICM contains automated function for material, tools and resource planning that are fixed to maintenance tasks. So all necessities are planned along with the maintenance plan. When you change the date of maintenance all dependencies move along with is. |

|

|

|

Reduce field time & enlarge your coverageHave technicians in a car, plane or walk over for an inspection is a washed of time and capacity. There are may options to remotely execute a first line analyses and have machines report their status autonomously. OpenICM offers all connections from SMS, Remote access up to Video streaming. We believe that remote maintenance should be as easy as making a telephone call so all our remote solution are click and go. Via our partners HMS and Bosch we offer high quality industrial grade systems. |