Find your best IIoT solution

IIoT offers many new technical and business possibilities however; IIoT depends on hardware and IT infrastructure. Especially for industrial use there are many things to consider in making the right choice for your situation.

Questions we have been asking our self’s when we started UVS IIoT way back in 2008. While IoT evolved into many public and private applications, industrial applications have shown a much slower adaptation. One of many reasons is that this technology needs to be reliable, rugged and safe to be used in and industrial environment.

UVS IIoTEngine and SMART Sensor technology makes it possible to measure, analyze and transport relevant data while keeping context and use minimal bandwidth.

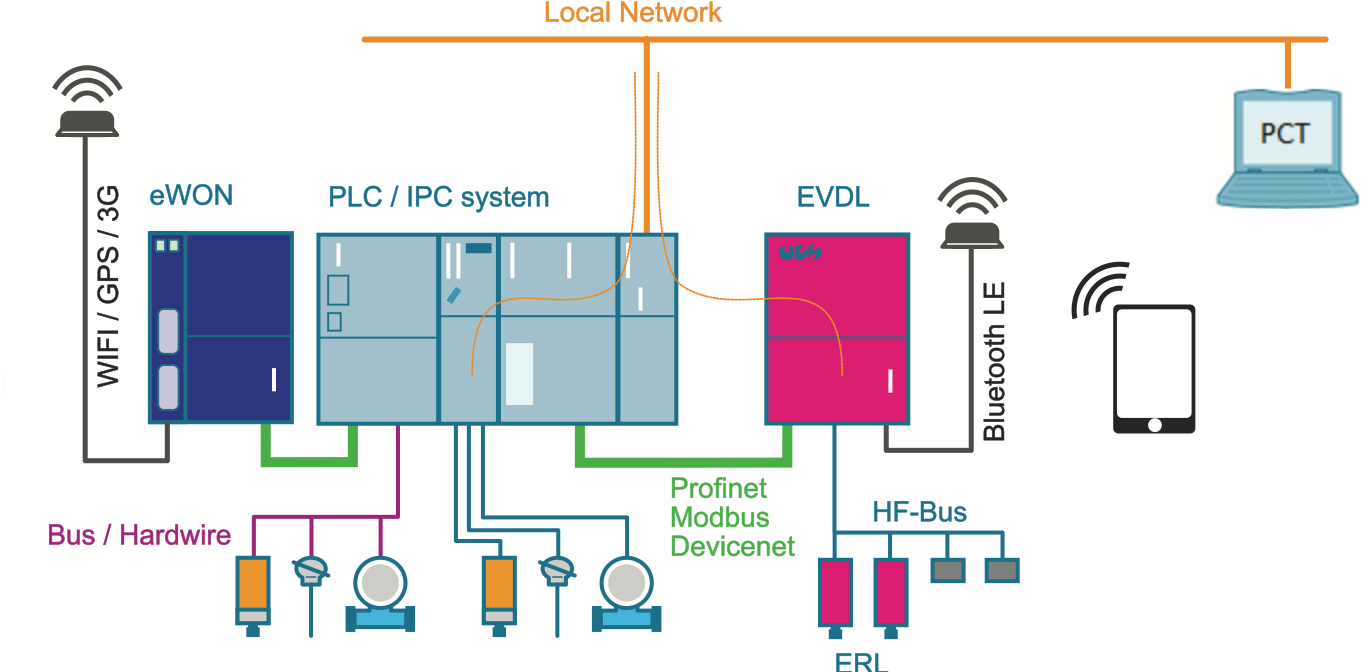

Picture (a) shows a traditional OT solution, all data is collected, abstracted and transported. Finally data is interpreted in an office environment. Big problem with this configuration is the amount of data that needs to be communicated; this can be Terabytes per day. Interpretation and analyses of these amounts of data will eat up huge amounts of processing power.

Pictuve (b) shows the UVS IIoT solutions where data is interpreted at the Edge and only relevant data is communicated for interpretation. Both bandwidth and reaction speed greatly benefit form this approach.

EDGE Connect

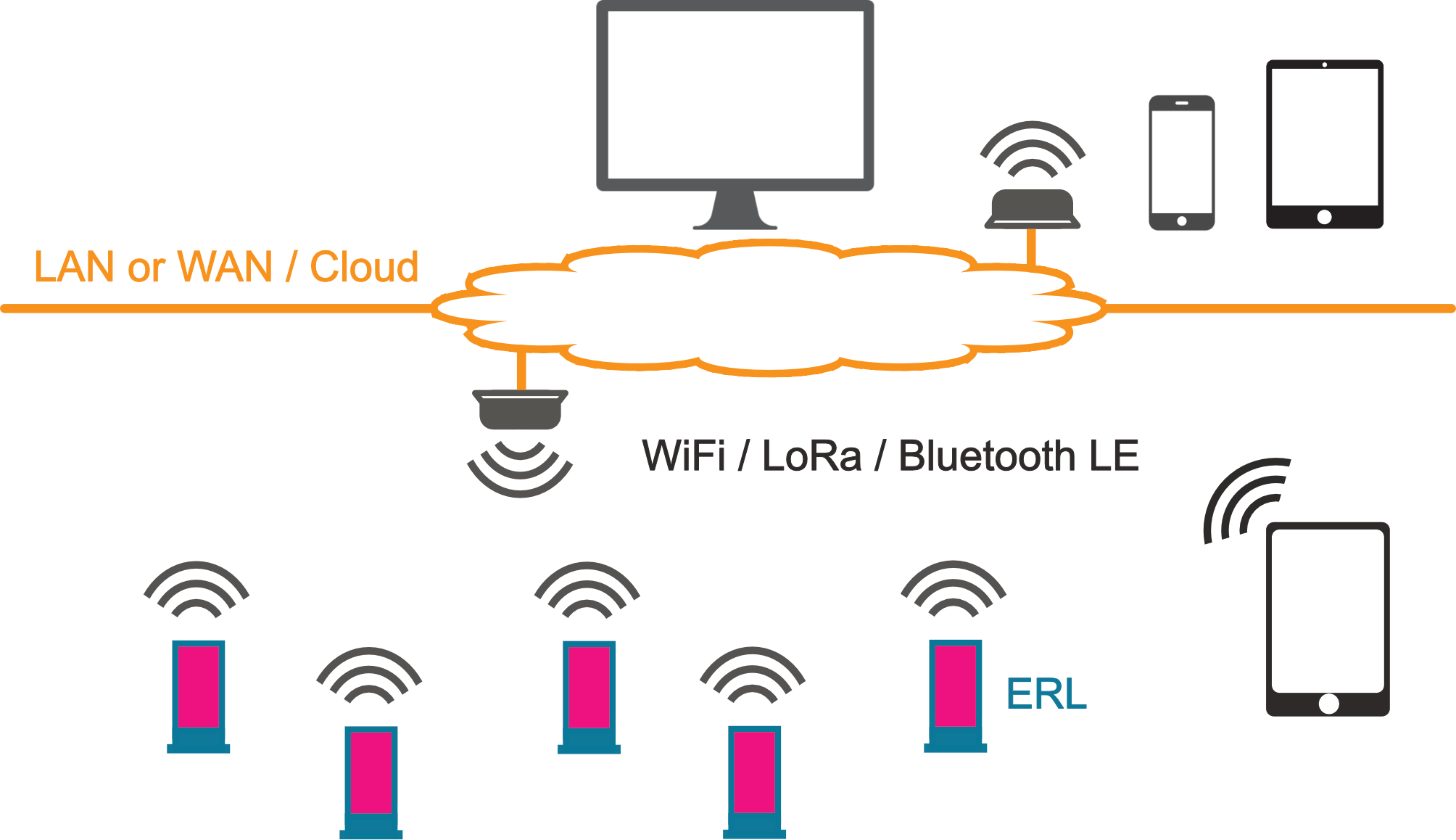

Situations with single measurements or geometrically widely spread sensors

Local Wireless

Measure without obstructing existing IT infrastructure. Quick and Easy.

Remote Access

Access data and control systems from any place in the world.

Local Streaming

Local high resolution data streaming to SCADA or mobile device.

Local wireless monitoring

Whether you already have a control system in place or building a completely new system, an EVDL makes it possible to view process- and historical parameters wirelessly. Most of the cases there is no need to change anything in the control-system.

When multiple measurement are applicable and maybe your would to make use of parameters that are already available inside the process control system like PLC or DCS you are most likely will use and EVDL as your data collector. A typical configuration looks like the one below.Remote BASE monitoring

Situations with single measurements or geometrically widely spread sensors, you could consider a configuration where devices connect to a cloud based server individually. This is a true IoT concept. This concept has some power management considerations, however it’s the most scalable and flexible configuration.

Local wireless monitoringRemote EDGE monitoring

In cases where not only warning and remote monitoring is required you will be looking at a remote access solutions. In this configuration you will be able to program control systems. It maybe clear that this incorporates security issues.

Remote ACCESS